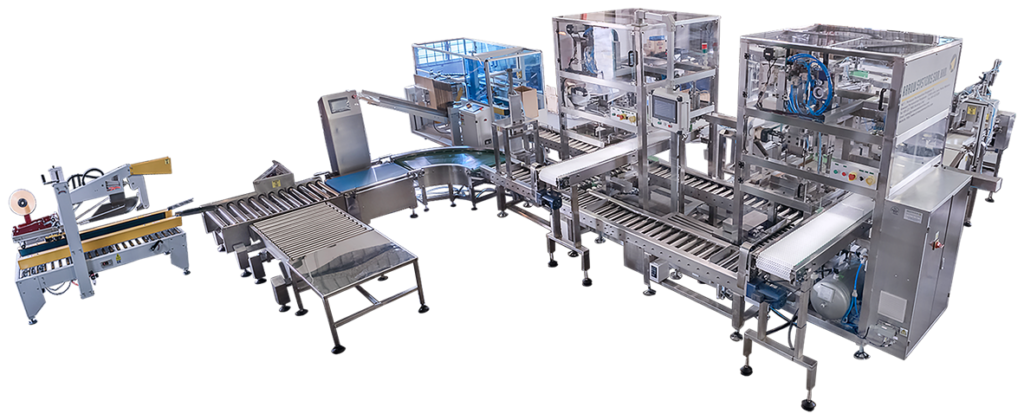

End of Line (EOL) Packaging Solutions

Our EOL packaging solutions are designed to automate the packaging and pre-packaging processes. Our customers can use the EOL packaging solutions to carry out sorting, measuring and inspection activities on ready-made Food and Beverage (F&B) products, and subsequently fill, wrap, pack and seal in various forms of packaging types prior to distribution.

By leveraging on our experience in delivering FOL processing solutions, we have developed insights in the pre-packaging and packaging needs of our customers, thereby allowing us to propose EOL packaging solutions that can be integrated with the FOL processing solutions.

We develop our internal capabilities to Design and Development (D&D), fabricate, install, test and commission EOL packaging solutions as an effort to offer an integrated end-to-end machinery solution.

Our EOL packaging solutions are designed and manufactured with the aim of:

(i) automatically sorting final products based on weight, volume or product combination for consistency of products to be packaged;

(ii) automatically measuring products based on weight or volume to improve consistency while minimising wastages;

(iii) automatically inspecting products based on quality parameters determined by our customers to achieve consistent and optimal quality control of final products;

(iv) achieving production efficiency through optimal utilisation of resources, such as packaging materials used as well as increased automation and output per hour, thereby achieving the desired capacity of our customers;

(v) reducing dependency on labour; and

(vi) optimising spatial allocation, based on available space in our customers’ premises for our EOL packaging solutions.

In the D&D of the EOL packaging solutions, our D&D activities are undertaken jointly and in consultation with our customers to understand the pre-packaging and packaging needs of our customers in the manufacturing business. Typically, our D&D department will take into consideration factors such as weight, colour consistency, product type and packaging layout which would determine the design of the EOL packaging solutions and the embedded components.

The range of applications for our EOL packaging solutions comprise:

a) Primary packaging: The first layer of packaging that comes in direct contact with the product. It is designed to protect the product and provide important information to the consumer.

b) Secondary packaging: A second layer of packaging that groups primary packaged products together, which can be in the form of boxes, plastic bags and other forms of packaging. It is used for branding, additional protection, and ease of handling during transportation and storage.

c) Tertiary packaging: A final layer of packaging purposed for the bulk handling, storage, and transportation of a batch of secondary packaged products. It is designed to ensure that large quantities of goods are safely transported from the manufacturer to the retailer or distributors.

We are able to customise the following equipment in our EOL packaging solutions to achieve the packaging requirements of our customers:

• Vision inspection modules: to detect faults in the products that are being inspected;

• Weighing modules: to ensure precise weight of products being packed to minimise waste;

• Robotic arms: to eliminate non-conforming products, pick and place products for pre-packaging and final packaging;

• Control systems: to improve the efficiency of automated sorting, measuring, inspecting and packaging of products; and

• IoT enabled modules: to enable remote connectivity for smart operations of the EOL packaging solutions which include access to reports, notifications, real-time monitoring, QC, machinery performance analysis and data analytics of our automation machinery solutions

Our D&D department will design and develop the prototype for the EOL packaging solutions based on the requirements of our customers. Depending on the project specifications, we can fabricate internally and may also engage third party fabricators to manufacture the equipment and components of our EOL packaging solutions. We typically source components such as weighing modules, robotic arms and IoT enabled modules from third party manufacturers.

Our technical department will undertake Quality Assurance (QA) and Quality Control (QC) on the equipment prior to the assembly activities. Thereafter, our technical department will undertake testing and commissioning of the EOL processing solutions prior to the installation at the manufacturing premises of our customers.