Front of Line (FOL) Processing Solutions

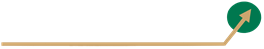

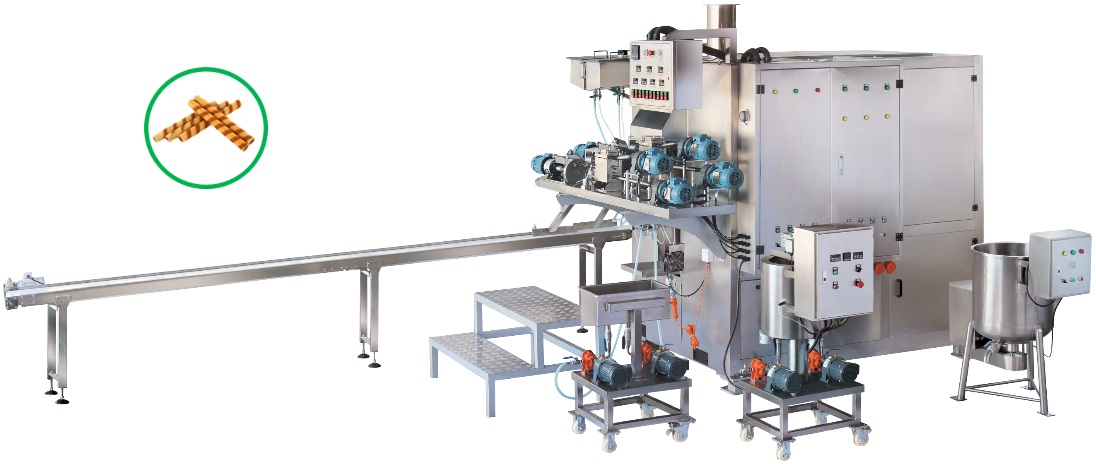

Our Group primarily provides FOL processing solutions for customers in the Food and Beverage (F&B) manufacturing industry. Our FOL processing solutions are designed to automate the manufacturing process of F&B products, where it transforms the raw ingredients into finished products. Through our FOL processing solutions, our customer can mix and combine the raw food ingredients to produce market-ready F&B products that are ready to serve.

We have developed internal capabilities supported by our team’s technical knowledge and experience in the Design & Development (D&D), fabrication, installation, testing and commissioning of FOL processing solutions to meet the performance objectives of our customers. These performance objectives typically encompass improving production volume, quality and safety while reducing cost, environmental footprint and dependency on labour. We primarily provide FOL processing solutions for customers in the F&B manufacturing industry.

Our FOL processing solutions are designed and manufactured with the aim of:

(i) achieving production efficiency through optimal utilisation of resources, such as raw materials used and energy costs, as well as increasing automation and production output per hour, thereby achieving the desired production capacity of our customers;

(ii) optimising spatial allocation, based on available space in our customers’ premises for our automated processing lines;

(iii) manufacturing quality end-products that meet our customers’ specifications, in terms of end-product attributes such as colour, shape, length, weight, thickness and taste;

(iv) automating manufacturing processes that are traditionally carried out by human labour; and

(v) achieving cost savings in the manufacturing processes of our customers.

Our D&D activities are undertaken jointly and in consultation with our customers to understand the product formulations, including features such as colour, shape, texture, length, weight, thickness and taste of the F&B product during the production process. This determines the D&D of the FOL processing solutions and its embedded components.

We are able to customise the following equipment in our FOL processing solutions to achieve the production requirements of our customers:

Mixer: in terms of dimensions and air flow, due consideration given for optimal mixing of wet and dry ingredients to ensure smooth and aerated mix for consistent end products in terms of taste and texture.

Extrusion machine: provided with multiple mould design options, due consideration given to moisture and expansion ratio to produce consistent end products in terms of shape, length, weight and thickness.

Cutters: designed to produce specific shapes, size and texture, to meet the specific cut sizes of food products or food production processing needs.

Ovens: in terms of dimensions, air flow, baking time and temperature, due consideration given to minimising heat loss, and heat requirements during the heating process as it affects the colour, shape, texture, length, weight, thickness and taste of the end product being produced.

Coating system: designed to apply specific coatings such as batters, breading, seasonings or glazes to food products in a precise and controlled manner, and are tailored to meet the requirements of different food products and production processes.

Conveyor belts: in terms of direction and length, to ensure sufficient cooling of food product, while taking into consideration the spatial limitations in the manufacturing premises of our customers.

Drum roaster: in terms of dimensions and air flow, roasting time and speed as well as temperature, due consideration given to heat requirements during the heating process as it affects the colour, taste, flavour and texture of the end product being produced.

Our D&D department will design and develop the prototype for the FOL processing solutions based on the requirements of our customers. We source components such as motors, gearboxes, conveyor belts and electrical circuit boards, actuators and sensors from third party suppliers. Our technical department will undertake QA and QC on our own fabricated components and the sourced components prior to the assembly activities. Thereafter, our technical department will undertake testing and commissioning of the FOL processing solutions prior to the installation at the manufacturing premises of our customers.